hardness test means|types of hardness testing methods : mfg Hardness testing may not be a fundamental physical property, but that does not mean it is not an important property to test and measure. This article discusses methods and the principles behind hardness testing.

WEBTelegram: Contact @eumariavilaa. Mari Ávila 👑🌸. 138 244 subscribers. View in Telegram. Preview channel.

{plog:ftitle_list}

WEB6 dias atrás · Taylor Russell — Foto: @tayrussell. Ouvir: Na onda dos cabelos curtos, o pixie promete ser o corte da temporada 0:00. O corte pixie está de volta com força .

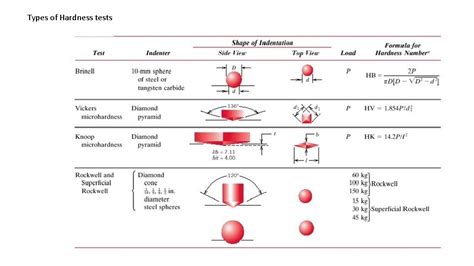

types of hardness tests

Hardness is the mechanical resistance of a material (specimen) to mechanical indentation by another harder body (indenter). The hardest natural material is the diamond, which is used for the indenter (industrial diamond).The principle of electronically controlled and permanently monitored load application .A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by . A hardness test is a method employed to measure the hardness of a material. Hardness refers to a material’s resistance to permanent indentation. There are numerous .

Hardness Testing. Discover the intricate world of hardness testing in materials engineering. This comprehensive guide delves into the definition, standards, procedure, and vital importance of . Hardness testing may not be a fundamental physical property, but that does not mean it is not an important property to test and measure. This article discusses methods and the principles behind hardness testing.Hardness Testing Basics. Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the .

Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the permanent depth of the .Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The large size of indentation and possible damage to test-piece limits its .What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a .The Vickers hardness test is a versatile hardness test method, used for both macro and micro hardness testing. It has a broad load range, and is suitable for a wide range of applications and materials. . The Vickers hardness test is .

In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation.Rockwell Hardness Test: This method assesses the depth of indentation caused by a specific load on the material’s surface. It’s highly versatile and straightforward, making it widely used across industries. Brinell Hardness Test: Using a spherical indenter, this test determines the hardness by measuring the diameter of the indentation .The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the hardness of materials with relatively low hardness ranges, such as non-ferrous metals, castings, and softer steels.

Hardness testing is the procedure used to determine the hardness of a material. The results allow properties of the material such as strength, wear-resistance and ductility to be empirically determined. This means the operator’s expertise and knowledge of the material are needed to determine these properties. Common hardness testing methods are introduced below. Rockwell Hardness. This method tests the hardness of steel parts by applying loads to parts via either a tungsten carbide ball or a spheroconical diamond indenter. A part’s testing surface and seating surface must be properly prepared prior to testing.

Hardness testing such as Vicker & Rockwell hardness requires the test surface to be prepared by fine polishing to measure the accurate indentation size & hence the material need to be destroyed- So, one can consider it Destructive Testing. . The Brinell tests are reported as “75 HB 5/1000/20” which means a Brinell Hardness of 75 was .

Rockwell hardness test is the most commonly used method for indentation hardness measurements. The value of Rockwell hardness is accompanied by the scale used. Depending on the material being tested, an appropriate scale must be selected. This hardness scale gives information on the type of indenter-load combination used.

2. Brinell Hardness Test Procedure. The Brinell Hardness Test is performed in a Brinell Hardness Test Unit. In this test method, a predetermined force (F) is applied to a tungsten carbide ball of fixed diameter (D), held for a predetermined time period, and then removed.

When diamond cones are used, the Rockwell scale is thus divided into 100 degrees of hardness. The testing method with a diamond cone is particularly suitable for very hard materials such as hardened or tempered steels. Apart from special procedures, the preload is 98 N (10 kp). The actual test load can vary depending on the application. First developed over one hundred years ago, the Rockwell hardness test is a rapid hardness testing method primarily used for quality assurance and production control. It uses a diamond cone or steel ball to first apply a minor load of around 3kgf before an additional major load is applied; typically, exceeding 10kg. . 🧴Method 1: Simple Soap Test. The soap test is a great way to determine water hardness.It won’t tell you exactly how hard or soft your water is, but it’s a quick and easy indicator of whether or not you have hard water.. You will need: A clear plastic bottle with a lid; Pure liquid soap; A water sample from your faucet A hardness test is a method employed to measure the hardness of a material. Hardness refers to a material’s resistance to permanent indentation. There are numerous techniques to measure hardness and each of these tests can identify varying hardness values for a single material under testing. Hence, hardness test as a method can be dependent .

An extensive range of specimen geometries can also be tested with the application of the hardness testing method. Hardness testing is an essential tool when it comes to differentiating various materials, as well as .

types of hardness testing methods

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring-loaded indenter made of hardened steel to indent the material/specimen.The indentation depth is a measurement for Shore hardness, that is .

Mohs hardness kit, containing one specimen of each mineral on the ten-point hardness scale. The Mohs scale (/ m oʊ z / MOHZ) of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of minerals through the ability of harder material to scratch softer material.. The scale was introduced in 1812 by the German geologist and mineralogist .Mohs hardness, rough measure of the resistance of a smooth surface to scratching or abrasion, expressed in terms of a scale devised (1812) by the German mineralogist Friedrich Mohs. The Mohs hardness of a mineral is determined by observing whether its surface is scratched by a substance of known or . For this reason the Mohs test, while . The Brinell test is described in ASTM E10 – 18 (Standard Test Method for Brinell Hardness of Metallic Materials). Advertisement. Rockwell Hardness Test. The Rockwell hardness test evaluates the hardness of a material by measuring the permanent depth of indentation due to an applied concentrated load. The higher the number on the Rockwell .Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that will be applicable depending on the hardness needed. Heat Treatment Evaluation: Using the assessment of the hardness of the treated .

Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5)The Janka hardness test (English: / ˈ dʒ æ ŋ k ə /; [1] German:), created by Austrian-born American researcher Gabriel Janka (1864–1932), measures the resistance of a sample of wood to denting and wear. [citation needed] It measures the force required to embed an 11.28-millimeter-diameter (7 ⁄ 16 in) steel ball halfway into a sample of wood.(The diameter was chosen to .Two inline skate wheels with different durometer – 85A and 83A Digital Shore hardness tester. The Shore durometer is a device for measuring the hardness of a material, typically of polymers. [1]Higher numbers on the scale indicate a greater resistance to indentation and thus harder materials. Lower numbers indicate less resistance and softer materials.

Hardness Testing Considerations The following sample characteristics should be consider prior to selecting the hardness testing method to use: • Material • Sample Size • Thickness • Scale • Shape of sample, round, cylindrical, flat, irregular • Gage R & R Material The type of material and expected hardness will determine test method. Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to .

Portable Digital Soil Moisture Meter fabrication

Canal Nickelodeon. Showrunner Dan Schneider. Atual → Séries → Netflix → Victorious. Victorious. Veja em Netflix. Veja em Paramount+. Veja em Nickhits Amazon Channel. 🇺🇸. .

hardness test means|types of hardness testing methods